| EC Certificate of Conformity: | 0757-CPD-287-11-001 tested according to DIN EN 12101-1 | |

| Class: | D30 - D120 (Temperature 600°C) DH30 - DH120 (Temperature ETK1100°C) | |

| Closing directions: | vertical, horizontal or curved | |

| Closing cycles: | 1.000 cycles pursuant to test standard |

You can obtain our smoke barrier in separation-free system widths that can be greater than 60 m both in class D30 – D120 and class DH30 – DH120.

Optionally available with standard end rail (galvanised sheet steel) or with flexible end strip.

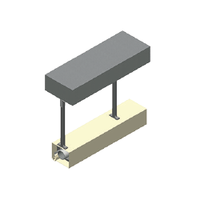

Lateral guide rails allow for 0% leakage, prevent the system from being displaced, and allow for a tight and self-closing seal made of non-flammable materials.

Take advantage of our innovative, ball-bearing mounted guide rails that ensure secure and low-wear closing and opening, even in a draught.

Wicket door options can be optionally integrated as well.

The flexible smoke barrier can be retrofitted into a textile-flexible smoke protection closure or a textile flexible fire protection closure at any time

Functionality

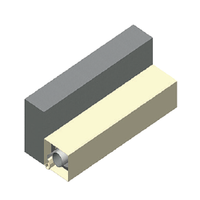

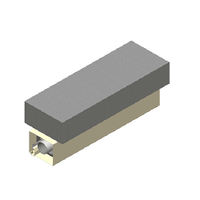

When opened, the textile is located on a winding shaft in an enclosure made of galvanised sheet steel above the opening to be closed.

The winding shaft is held in the opened position by a magnetic clamp integrated in the tubular motor. The system closes in a speed-controlled manner under its own weight according to the gravity fail safe principle by means of an end rail. The closing speed is approx. 10 - 15 cm per second.

Wiring with functional integrity is not required due to the gravity fail safe principle.

Motor controllers, additional accessory components, as well as installation variations can be found in the section Control units.

Installation options

Guide rails

End strips