| Certificate of Constancy of Performance: | 1322-CPR-65797/02 certified according to EN 1634-1 | |

| Class: | EI30 – EI60 | |

| Closing cycles: | C - C1 depending on model (e.g. size, weight) | |

| Closing direction: | vertical |

Standard system sizes up to 6.6 x 4.5 metres (approx. 30 m2). larger dimensions possible as special systems!

Dry system (no sprinkler protection / no water pressurisation required).

In addition to fire protection, we are relying on the use of renewable, domestic, recyclable, and natural raw materials for our new TFF-EI product line.

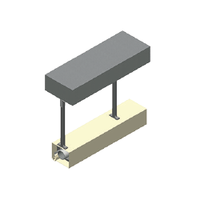

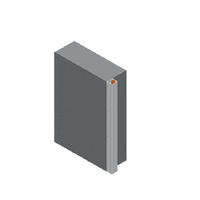

The lateral guide rails made of wood (solid oak), a 100% natural raw material, can be ideally integrated into existing architectural specifications. The winding shaft can frequently be installed without further covering and thus optimally integrated, for example, in suspended ceilings. The winding shaft can be optionally covered with a housing made of galvanised sheet steel, wood, or with drywall.

The end strip consists of a textile bag, in which the closing weight is built in (colour of textile bag: anthracite).

All wood and sheet steel parts can be designed in the desired RAL colour upon request.

With the TFF-EI as well, the special fabric (with expanding material) is guided in the lateral guide rails by means of ball bearings, which ensure reliable and low-wear closing and opening even in a draught.

In addition to the standard model, the TFF-EI can also be used as a floor-closing variation at an elevated installation height, on façades (interior), and throughout track-bound conveyor systems.

Functionality

When opened, the textile is located on a winding shaft (optional in a housing made of galvanised sheet steel) above the opening to be closed.

The winding shaft is held in the opened position by a magnetic clamp integrated in the tubular motor. The system closes in a speed-controlled manner under its own weight according to the gravity fail safe principle by means of an end rail. The closing speed is approx. 10 - 15 cm per second.

Wiring with functional integrity is not required due to the gravity fail safe principle.

Motor controllers, additional accessory components, as well as installation variations can be found in the section Control units.

Housing

Guide rails

End strips

Surfaces

- Powder-coated in RAL-/DB colours according to customer request (optional)

- Painting in NCS colours according to customer request (optional)