| Allgemein bauaufsichtliche Zulassung: | Z-6.5-2225 (als Feststellanlage mit FAA) Z-6.5-2226 (als Feststellanlage ohne FAA) | |

| Gehäuse: | Stahlblech RAL 7035 (optional Edelstahlausführung) | |

| Abmessungen (BxHxT): | 380 x 380 x 210 mm | |

| Schutzart: | IP65 | |

| Eingangsspannung: | 230 V AC +10% / -15% | |

| Eingangsstrom: | max. 2 A | |

| Ausgangsspannung: | 24 V DC +/- 5 % |

Features / Highlights:

- Especially harmonized system components

- Very high flexibility based on configurable components

- Significant reduction of time planning thanks to use of standard components

- Sample circuit diagrams enable a project planning without a complex coordination and waiting times

- Short delivery times thanks to the use of prefabricated standard components

- Compact control consoles enable an operation even under unfavourable conditions

- Simplified assembly and cabling through an optimal designed system structure

- Reduction of start-up costs by customer-specific standards

- Flexible extension requiring only litte time and no high planning costs

- Quick change device for all system components

- Application range from single system up to Bus system for complex applications

- Including extensive documentation in all available languages

- Multilingual evaluation software for status information and events

- System data storage on a memory card integrated in the control unit

- Data export function for remote maintenance included

- Compact decentralized switch device unit for conveyor drive systems

- High performance emergency power supply from 2 kW, 4 kW and 9 kW

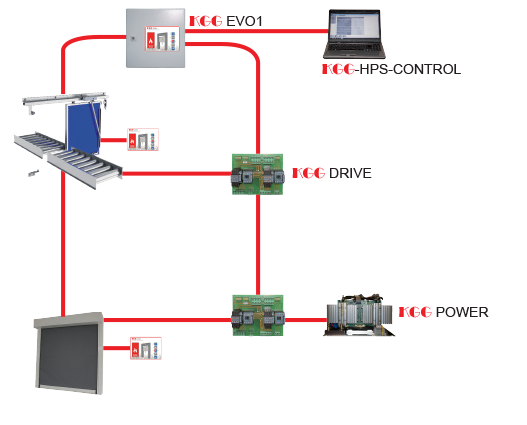

Intelligent control system

The solution is based on the following components:

- KGG EVO1 Hold-open device for several fire doors or gates

- KGG-HPS-CONTROL PC application for system monitoring

- KGG DRIVE Control unit for the conveyor drive systems

- KGG POWER Emergency power supply in case of power failure or loss of voltage

The implementation of standards enables an excellent basis for the efficient and cost-optimized realization of projects.

KGG EVO1

- Hold-open devices for fire protection doors or gates

- Control of several independent fire protection doors or gates possible

- Application range from single system up to Bus system for complex applications

- Substitute power supply according to DIN EN 54-4/A2 for 1 to 4.5 hours

- Multilingual touch panel and visualization of over 30 states

- Evaluation of up to 20 fire detectors

- Monitoring of the closing area for several conveyor sections

- System data storage and event buffer on removable memory card integrated in the control unit

- Transfer of parameter settings in case of a changeover to new hardware without system interference according to the DIBt/VdS requirement

- PC connection by USB interface for status information and event evaluation

- Including preparation for the connection to a conveyor technique BUS system

- Complete potential-free configurable interface to the conveyor technique

- Compact extension module for additional operating stations

- Integrable operating mode key switch

- Protection class: IP 65 - according to most of the industrial applications

KGG-HPS-CONTROL

- Protection class: IP 65 - according to most of the industrial applications

- Connection over USB interface

- Multilingual software in available languages

- Constant expension with further languages

- Integration of the system documentation into the installed languages

- Display of all current statuses of the connected control units

- Data export function for remote

KGG DRIVE

- Control unit for the conveyor drive systems

- Compact decentralized switch device unit for conveyor drive systems

- Standardized components with quick change function

- Design of the components in diff erent versions depending on the drive system

- Integration of emergency stop coupling according to EN954-1 KAT4 for the personal security requirement

- Exchangeable printboard for the rapid adaptation to diff erent conveyor drives

- Protection class IP65 - according to most of the industrial applications

KGG POWER

- Emergency power supply in case of power failure or loss of voltage

- Power range supply from 2 kW, 4kW and 9 kW – active power

- Parallel provision of 24 V DC/ 3~ 230 V AC/ 3~ 400 V AC possible

- Provision of 24 V for the buff ering of the conveyor technique emergency stop system.

- Independent control with diff erent voltages for the conveyor drives

- Charging device according to EN 54-4/ A2 with active, VdS tested battery monitoring

- Compact system cabinet for free positioning in the plant

- Protection class IP 54 - use also possible with sprinkler systems